ekta engineers

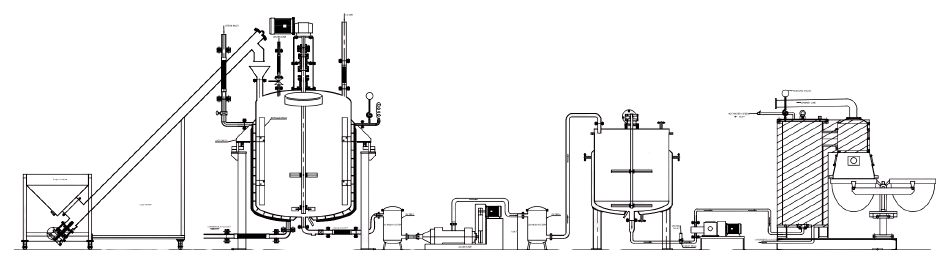

Manufacturers of Confectionery Cooking & Food Process Equipment

About Us

At Ekta Engineers, we are committed towards maintaining International Standards of quality in all aspects - from Equipment Design, Development & Installation to its Implementation. Known for the technical innovation & ease of operation, our equipment is customizable to suit our client’s requirements & convenience. Our technical expertise & professional consultancy services have benefited several leading companies.

- Our Leadership

- Naresh Chandnani, the Founder of Ekta Engineers has led Engineering & Equipment Development for over three decades now.

- Vision

- To become a trusted partner in providing end to end solutions in the Confectionery Industry.

- Mission

- To establish ourselves as a market leader in the Manufacturing of Confectionery Cooking & Food Process Equipment.

- Core Value

- We build success through shared progress, unwavering integrity, continuous refinement, and exceptional quality.

Meet Our Team

We’re a dynamic group of individuals who are passionate about what we do and dedicated to delivering the best results for our clients.

Director

Naresh Chandnani

Senior Design Engineer

Venugopal Reddy

Plant Head

Ram Ramnani

Our Esteemed Clients

Your Solution for Modern Food Production.

Our Location

- # 99, K.K Owners Society Phase V Extn.,

I.D.A Jeedimetla, Hyderabad - 500055

Telangana, India - Telephone

- +91 81253 25300 +91 98854 80111